- Electric Bus Charging Upgraded: Fast & Flexible

- Shenzhen Kehua’s 40 kW High-Efficiency SiC Charging Module Achieves CE, CB, and UL Certifications

- Shenzhen Kehua Unveils High-Reliability All-in-One DC Charger for the ASEAN Market

- Shenzhen Kehua’s Scalable Megawatt Power Unit: Pioneering the Next Era of High-Power Charging for Green Mobility

- Growth Opportunities in the EV Charging Industry Amid the Global Transportation Electrification

- The Future of Fleet Charging: Building Efficient and Reliable Charging Infrastructure

Content Menu

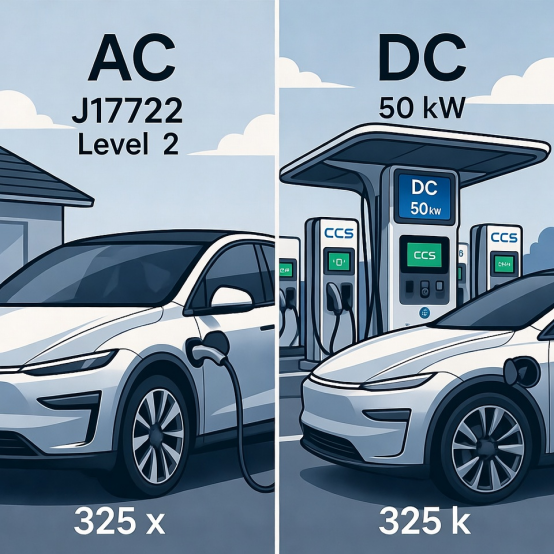

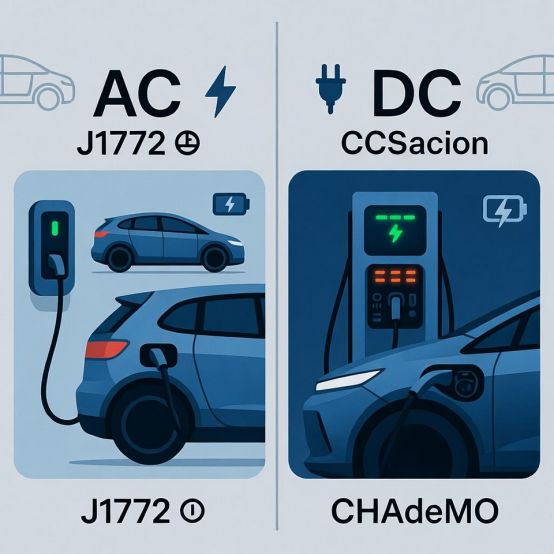

● How AC and DC EV Charging Work

>> The Grid Delivers AC, Batteries Store DC

>> AC Charging: Onboard Conversion Inside the Vehicle

>> DC Fast Charging: External Conversion for Maximum Power

● Levels of EV Charging: AC and DC in Practice

>> Level 1 AC Charging: Simple but Slow

>> Level 2 AC Charging: The Everyday Standard

>> DC Fast Charging: Rapid Refueling for Routes

>> Summary Table: Level 2 AC vs DC Fast Charging

● Installation, Grid Impact, and Cost: AC vs DC

>> AC Charging Installation: Residential-Friendly and Modular

>> DC Fast Charging Installation: Grid-Centric Infrastructure

● Battery Health: AC vs DC Charging Effects

>> AC Charging and Battery Longevity

>> DC Fast Charging and Accelerated Aging Factors

>> Practical Charging Strategies for Battery Care

● When to Choose AC vs DC Charging

>> Residential and Depot Charging: AC-First Strategy

>> Highway and Commercial Hubs: DC-Focused Strategy

>> Hybrid Networks: Combining AC and DC for Flexibility

● Charging-Infrastructure Decision Framework for CPOs and Fleets

>> Step 1: Map Vehicle Usage and Dwell Time

>> Step 2: Translate Energy Needs into Power Requirements

>> Step 3: Balance Capital Cost and Operational Goals

>> Step 4: Plan for Scalability

● Real-World Use Cases: AC vs DC in Action

>> Use Case 1: Urban Delivery Van Fleet

>> Use Case 2: Long-Distance Trucking Corridor Hub

● Call to Action: Build the Right AC and DC EV Charging Mix for Your Project

>> FAQ 1: Is AC charging always better for battery life than DC fast charging?

>> FAQ 2: How do I decide whether my site needs AC chargers, DC chargers, or both?

>> FAQ 3: Can the same EV use both AC and DC chargers?

>> FAQ 4: Does installing DC fast chargers always require a major grid upgrade?

>> FAQ 5: What is the most future-proof approach to EV charging infrastructure?

EV charging is no longer optional; it is critical infrastructure. Understanding the difference between AC and DC EV charging is essential for homeowners, fleet operators, and charging-point operators (CPOs) who want to design cost-effective, scalable, and EV-friendly charging networks in 2026 and beyond.

In short:

- AC charging uses alternating current from the grid; the vehicle's onboard charger converts it to DC before it reaches the battery.

- DC charging converts AC to DC inside the charging station itself and delivers high-power DC directly to the battery pack.

This single architectural difference affects charging speed, cost, installation complexity, grid impact, and long-term battery behavior. This guide explains how AC and DC charging work, how to choose between them for different scenarios, and how to plan robust charging infrastructure for private users, fleets, and commercial sites.

How AC and DC EV Charging Work

The Grid Delivers AC, Batteries Store DC

All conventional electrical grids deliver AC (alternating current), but EV batteries can only store DC (direct current). The core question is therefore not whether electricity is AC or DC at the source, but where the AC–DC conversion happens in the charging chain.

- With AC charging, the EV's onboard charger converts AC from the grid to DC for the battery.

- With DC fast charging, the charger performs that conversion and feeds DC directly into the battery terminals.

Because DC chargers use larger, externally cooled power electronics and bypass the onboard charger, they can deliver far higher power levels, which is why DC fast charging is significantly faster than AC charging.

AC Charging: Onboard Conversion Inside the Vehicle

Typical AC EV chargers deliver 3.7 kW to 22 kW, with most residential and commercial AC chargers operating in the 7 kW to 11 kW or 11 kW to 22 kW range. The actual charging speed is limited by the lower of:

- The maximum power of the EV's onboard charger (for example, 7.2 kW, 11 kW, or 22 kW).

- The available voltage and current at the installation site (single-phase or three-phase supply).

AC charging is ideal where vehicles are parked for longer periods. Typical applications include:

- Overnight residential charging at homes and apartment blocks.

- Workplace charging where vehicles stay parked for several hours.

- Fleet depots for light commercial vehicles and service vans.

Because conversion happens inside the vehicle, the external AC charger can remain relatively simple and cost-effective while still enabling smart features such as user authentication, billing, and load management.

DC Fast Charging: External Conversion for Maximum Power

DC fast chargers (often called Level 3 chargers) commonly deliver from 50 kW up to 350 kW, with next-generation systems for heavy-duty vehicles moving into the 500 kW to 1 MW range. Here, rectification and voltage boosting are performed inside the station, not in the car.

This allows the station to:

- Deliver significantly higher charging currents directly to the battery pack.

- Control power dynamically across multiple charging posts at a single site.

- Integrate with advanced smart grid and energy management systems.

The trade-off is that DC fast charging requires higher upfront investment, more complex grid connections, and more sophisticated thermal management, both in the charger and the vehicle's battery system.

Levels of EV Charging: AC and DC in Practice

Level 1 AC Charging: Simple but Slow

Level 1 charging uses a standard low-voltage single-phase outlet (for example, 120 V in North America). Charging power typically ranges from about 1.4 kW to 1.9 kW, adding only a few miles of range per hour.

Typical use cases:

- Occasional or emergency charging when no dedicated EV charger is available.

- Drivers with very short daily commutes and long overnight parking times.

- Temporary charging in locations where upgrades are not yet possible.

While convenient, Level 1 is generally too slow for modern EVs as a primary charging solution, especially for drivers who cover significant daily mileage.

Level 2 AC Charging: The Everyday Standard

Level 2 AC charging typically operates on 208 V or 240 V single-phase or three-phase supply, delivering 3 kW to 22 kW depending on the installation and the on-board charger limit. Many home and commercial AC chargers fall into the 7 kW to 11 kW or 11 kW to 22 kW bands.

Approximate range gain per hour of Level 2 AC charging:

|

Charging power (kW) |

Approximate added range per hour* |

|

3 – 7 kW |

10 – 30 miles |

|

7 – 11 kW |

30 – 60 miles |

|

11 – 22 kW |

40 – 100+ miles |

*Actual values depend on vehicle efficiency, temperature, and driving style.

Level 2 AC charging is the dominant standard for homes, workplaces, parking garages, and fleet depots because it offers a strong balance of speed, cost, and grid compatibility.

DC Fast Charging: Rapid Refueling for Routes

DC fast charging operates at much higher power levels, typically from 50 kW up to 350 kW or more. At 150 kW to 300 kW, many passenger EVs can reach around 80% state of charge in 20 to 40 minutes under favorable conditions.

Because the charger bypasses the onboard AC charger, the vehicle can accept high currents directly into the battery, limited mainly by the battery's chemistry, temperature, and the vehicle's internal control strategy. DC fast charging is the preferred solution for:

- Highway service areas and intercity corridors.

- Urban fast-charging hubs with high vehicle turnover.

- Commercial fleets with tight schedules and short dwell times.

For planners, the crucial insight is that DC fast charging behaves more like fueling infrastructure than parking infrastructure, with hardware sizing driven by peak throughput instead of static parking counts.

Summary Table: Level 2 AC vs DC Fast Charging

|

Feature |

Level 2 AC Charging |

DC Fast Charging |

|

Typical power level |

3 – 22 kW |

50 – 350+ kW |

|

Conversion location |

In-vehicle onboard charger |

In the external charger |

|

Typical charging time |

0 – 100% over several hours |

10 – 80% in 20 – 40 minutes |

|

Grid connection |

Generally residential or light commercial |

Industrial-grade, often with dedicated transformer |

|

Best suited for |

Homes, workplaces, depots, long parking |

Highways, logistics hubs, quick turnarounds |

Installation, Grid Impact, and Cost: AC vs DC

AC Charging Installation: Residential-Friendly and Modular

Installing Level 2 AC EV chargers is typically straightforward compared with DC fast charging. A standard installation includes:

- A dedicated 208–240 V circuit for each unit or shared capacity for a bank of chargers.

- A suitable breaker, cabling, and conduit sized to national and local electrical codes.

- Appropriate connectors such as Type 1 (J1772), Type 2, CCS, or region-specific standards.

Approximate cost drivers for AC charging installations include:

- Hardware cost per AC charger.

- Cable runs and conduit lengths from the electrical panel.

- Labor, permitting, and potential panel upgrades.

Because power levels are moderate, AC installations often avoid heavy transformer upgrades, making them a cost-effective choice for multi-stall residential and depot sites. Smart AC chargers also support dynamic load management, allowing site owners to cap total current draw and avoid demand peaks.

DC Fast Charging Installation: Grid-Centric Infrastructure

DC fast-charging systems require significantly more planning and investment. Typical steps include:

- Securing a high-capacity three-phase supply, often with a dedicated transformer.

- Completing detailed load studies and engaging the utility for capacity planning.

- Designing foundations, cable trenches, and ventilation or cooling infrastructure.

- Integrating payment systems, networking, and long-term service support.

Key cost drivers for DC fast charging are:

- High-power charger hardware and associated switchgear.

- Transformer and upstream grid upgrades.

- Civil works, including foundations, parking layout, and accessibility features.

Because DC fast chargers draw substantial power over short time windows, their business case is typically built around utilization metrics, energy pricing, and service revenue rather than simple hardware cost per stall.

Battery Health: AC vs DC Charging Effects

AC Charging and Battery Longevity

AC charging generally involves lower current and longer charging times, which aligns well with how battery management systems are designed to maintain cell balance and temperature control. This often results in:

- Gentler charge cycles and lower stress on cell chemistry.

- More time for the battery management system to balance cell voltage.

- Reduced risk of extreme temperature or voltage spikes.

As a rule of thumb, using Level 2 AC charging for the majority of daily charging needs is considered a good practice for maximizing long-term battery health.

DC Fast Charging and Accelerated Aging Factors

DC fast charging exposes batteries to much higher currents over shorter periods, which can accelerate certain aging mechanisms if poorly managed. Potential issues include:

- Increased cell temperatures, especially when charging from a low state of charge or in hot climates.

- Higher mechanical and chemical stress inside the electrodes at very high charge rates.

- Potential lithium plating risks under extreme conditions such as high current at low temperatures.

However, modern EVs and chargers limit these risks using advanced control strategies, including temperature-based charge limits, softened charging curves at very low and very high state of charge, and dynamic output adjustments based on real-time battery data.

Practical Charging Strategies for Battery Care

If you want to balance fast charging with battery health, consider the following guidelines:

- Use AC charging for routine, everyday energy needs whenever possible.

- Reserve DC fast charging for long trips, tight schedules, or unplanned situations.

- Avoid repeatedly charging to 100% on DC fast chargers unless absolutely necessary.

- Start fast charging at moderate state-of-charge levels instead of from very high or very low extremes where possible.

These strategies help users enjoy the convenience of DC fast charging without unnecessarily accelerating battery degradation.

When to Choose AC vs DC Charging

Residential and Depot Charging: AC-First Strategy

For residential users and most light-duty fleets, AC charging is usually the most efficient and cost-effective choice. Vehicles are parked for many hours overnight or during work shifts, and even moderate power levels can easily cover daily driving needs.

An AC-first strategy for homes and depots typically includes:

- Installing Level 2 AC chargers sized to the electrical panel capacity.

- Using smart scheduling or time-of-use tariffs to charge when electricity is cheaper.

- Integrating rooftop solar or other distributed energy resources where available.

This approach minimizes installation complexity, reduces grid stress, and offers predictable operating costs while still providing sufficient charging speed.

Highway and Commercial Hubs: DC-Focused Strategy

On highways, major arterial roads, logistics hubs, and high-traffic commercial parking, DC fast charging becomes critical. Drivers and fleet managers in these locations prioritize turnaround time over installation cost, and high utilization can justify the investment in fast-charging infrastructure.

Key deployment considerations:

- Locate DC fast-charging stations along high-demand routes or at strategic hubs.

- Design modular systems that can be expanded as EV adoption increases.

- Combine large DC chargers with a few AC chargers to handle longer-stay vehicles without congesting fast chargers.

In these environments, DC charging operates alongside retail, rest, or logistics services, enabling drivers to recharge both their vehicles and themselves in a single stop.

Hybrid Networks: Combining AC and DC for Flexibility

The most resilient and future-ready charging networks combine AC and DC charging in a layered design. AC chargers handle the routine, high-dwell charging needs, while DC chargers support peak-throughput and route-critical stops.

A hybrid network provides:

- Cost-effective coverage for everyday charging demands.

- Strategic fast-charging capacity for long-distance travel and high-value use cases.

- Flexibility to adapt as vehicle types, usage patterns, and energy prices evolve.

For charging network operators and equipment providers, offering both AC and DC solutions ensures that customers can build tailored, end-to-end EV charging ecosystems rather than isolated projects.

Charging-Infrastructure Decision Framework for CPOs and Fleets

Step 1: Map Vehicle Usage and Dwell Time

Begin by mapping out how vehicles actually operate:

- Daily distance per vehicle and peak days.

- Typical parking durations at home, depot, or on route.

- Vehicle mix, including passenger cars, vans, trucks, and buses.

Longer dwell times favor AC charging, while short, predictable stops along high-traffic routes support DC deployments.

Step 2: Translate Energy Needs into Power Requirements

Estimate the daily energy requirement (kWh) per vehicle and convert it into required charging power and time. Then compare this to available grid capacity and your desired margin of safety.

- If behind-the-meter capacity is constrained, prioritize AC chargers with smart load management.

- If you expect high-throughput commercial use, plan for DC chargers with staged power modules.

Step 3: Balance Capital Cost and Operational Goals

|

Decision axis |

Favors AC |

Favors DC |

|

Average dwell time |

Long (3+ hours) |

Short (< 1 hour) |

|

Grid capacity |

Limited or expensive to upgrade |

Strong, near existing transformers |

|

Budget focus |

Capex-sensitive |

Revenue or SLA-driven |

|

Battery life emphasis |

High priority |

Medium priority |

Use this simple matrix to settle on an AC-prime, DC-prime, or hybrid network design that aligns with both technical constraints and business goals.

Step 4: Plan for Scalability

Regardless of the initial mix, design your infrastructure to scale. This can include:

- Leaving space and conduit for additional chargers.

- Installing switchgear sized for future power increases.

- Selecting chargers compatible with open communication standards and flexible software platforms.

Scalability ensures that your investment can support not only existing EVs, but also next-generation vehicles with larger batteries and higher charging speeds.

Real-World Use Cases: AC vs DC in Action

Use Case 1: Urban Delivery Van Fleet

Imagine a fleet of 20 electric delivery vans, each covering roughly 60 miles per day and returning to a depot for 10 to 12 hours overnight. In this scenario, Level 2 AC charging at 7 kW to 11 kW per vehicle is typically sufficient.

A practical setup might include:

- An AC charger at each parking bay or shared AC chargers with scheduled charging.

- Smart load balancing to ensure the depot's maximum current limit is never exceeded.

- Time-of-use charging to reduce energy costs during off-peak hours.

This approach keeps operating costs predictable, avoids heavy grid upgrades, and maintains battery health with gentle overnight charging cycles.

Use Case 2: Long-Distance Trucking Corridor Hub

Now consider a highway hub serving hundreds of heavy-duty electric trucks every day, each with strict delivery schedules and limited time to stop. Here, DC fast charging with power levels of 350 kW or more is essential.

An effective configuration could include:

- Multiple high-power DC chargers in parallel to serve several trucks at once.

- On-site energy storage or load management to reduce utility demand charges.

- Integration with fleet-telemetry systems for reservation and scheduling.

In this use case, rapid DC charging directly supports business-critical logistics performance and route reliability.

Call to Action: Build the Right AC and DC EV Charging Mix for Your Project

The real power of understanding the difference between AC and DC EV charging lies in your next infrastructure decision. Whether you are planning residential solutions, workplace charging, public parking, or high-throughput highway hubs, choosing the right mix of AC chargers, DC fast chargers, and megawatt-class systems will determine your long-term cost, scalability, and user satisfaction.

If you are evaluating AC and DC EV charging solutions for your next project, contact our team at Shenzhen Kehua Hengsheng Technology Co., Ltd. for a tailored design. We offer a full portfolio that includes DC charging modules, AC chargers, DC fast chargers, high-power distributed systems, and megawatt-class charging platforms, helping you build a robust, end-to-end EV charging network that matches today's demand and tomorrow's growth.

FAQ: AC vs DC EV Charging

FAQ 1: Is AC charging always better for battery life than DC fast charging?

AC charging is generally gentler because it uses lower power over longer periods, which aligns well with how EV batteries are designed to operate. However, modern DC fast charging, when used as intended, is engineered to stay within safe limits. Occasional DC fast charging for long trips should not cause dramatic degradation, but relying almost exclusively on DC fast charging may increase battery wear over many years.

FAQ 2: How do I decide whether my site needs AC chargers, DC chargers, or both?

Start by looking at dwell time, daily energy demand, and available grid capacity. If vehicles typically park for several hours, Level 2 AC chargers are often sufficient and more cost-effective. If you serve drivers who only stop briefly or you operate a high-throughput commercial hub, you will likely need DC fast charging as well. Many sites benefit from a hybrid layout blending AC and DC solutions.

FAQ 3: Can the same EV use both AC and DC chargers?

Most modern EVs can charge on AC and DC as long as they support the relevant connector standards. AC charging uses the onboard charger and common connectors such as Type 1 or Type 2, while DC fast charging uses standards like CCS, CHAdeMO, or region-specific plugs. Check your vehicle's specifications to see which standards and maximum power levels it supports.

FAQ 4: Does installing DC fast chargers always require a major grid upgrade?

Not always, but it is common. High-power DC fast chargers draw significantly more current than typical AC chargers, so utilities often need to assess whether the local grid can support the new load. In some cases, deploying on-site energy storage or limiting simultaneous output across multiple DC chargers can reduce peak demand and minimize grid upgrades.

FAQ 5: What is the most future-proof approach to EV charging infrastructure?

A future-proof strategy typically combines flexible AC charging for everyday use with strategically placed DC fast charging for long-distance travel and high-priority operations. Choosing modular hardware, open communication protocols, and scalable electrical designs ensures that your infrastructure can adapt to larger batteries, faster charging standards, and growing vehicle volumes over time.

References

1- https://autelenergy.com/global/resources/blog/what-is-the-difference-between-ac-and-dc-ev-charging

2- https://store.autelenergy.com/blogs/blog/ac-chargers-vs-dc-chargers

3- https://blog.evbox.com/uk-en/difference-between-ac-and-dc

4- https://go-e.com/en/magazine/ac-dc-charging

5- https://www.energyefficiency.ie/blog/ac-v-dc-electric-vehicle-charging

Hot Tags: AC vs DC EV Charging, AC EV Charging, DC EV Charging Comparison, EV Charging Speed Differences, Alternating Current Charging, Direct Current Fast Charging, EV Power Conversion, Home Vs Fast Charging, EV Charging Efficiency, EV Charger Power Types, Electric Car Charging Basics