In 2023, the 800V electric vehicle market reached a size of $386.7 billion and is expected to grow to $998.2 billion by the end of 2030, with a compound annual growth rate (CAGR) of 15.4% from 2024 to 2030. This growth reflects the growing popularity of high-voltage electric vehicles and the growing need for faster charging solutions.【1】

According to the "2023 McKinsey China Auto Consumer Insights," electric vehicle consumers are most concerned about cruising range and charging duration. As many as 56% of respondents consider these factors extremely important, far surpassing the second and third concerns of dynamic performance (48%) and cost of vehicle ownership (46%). This further highlights the urgency for faster charging.

Demand for High-Power Fast Charging Stations

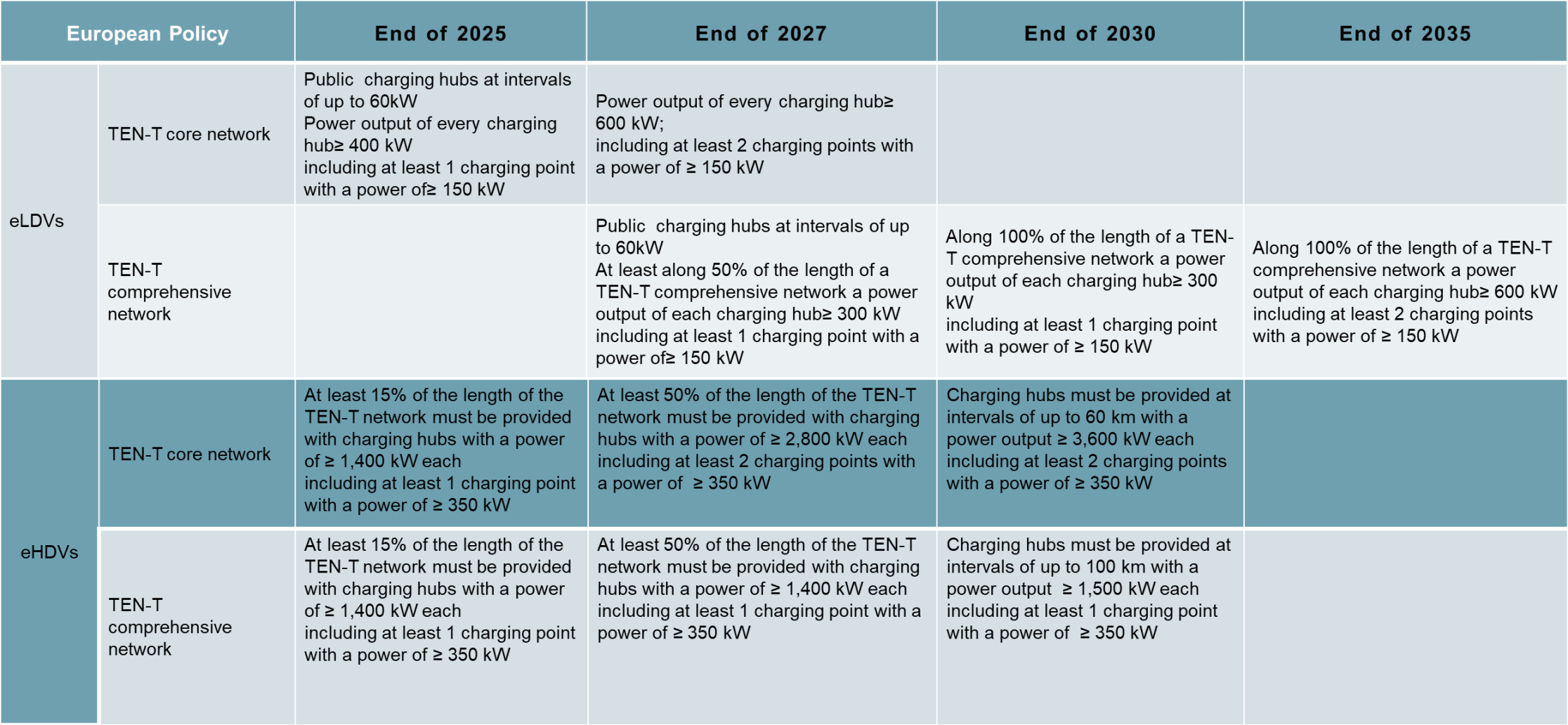

To meet the needs of high-voltage fast-charging vehicles, the deployment of high-power fast charging stations has become crucial. According to Kehua’s estimates, to achieve rapid charging within 5 minutes, the power output of charging stations must be increased to 480kW. In response to the future trend of high-power fast charging, major automakers and charging operators have begun deploying high-power fast charging stations. Europe has also formulated corresponding policies for charging stations to address the growing demand.

High-voltage fast charging stations can significantly reduce charging time. However, there are still some challenges that need to be overcome:

- Tolerance and Power Density of Charging Modules: The ability of charging modules to withstand higher voltages and maintain power density is critical.

- Heat Dissipation Capability and Energy Loss: Managing heat dissipation and minimizing energy loss under higher currents and switching frequencies is a major challenge. High-power charging can affect battery stability, leading to adverse effects such as battery degradation and fire.

- Reliability in Harsh Conditions: Ensuring the safety and stability of equipment under extreme conditions such as high temperatures, high humidity, salt spray, and dust is crucial. This requires using highly reliable materials to manufacture components that can withstand these conditions.

Addressing High-Voltage Fast Charging Challenges

To address the challenges associated with high-voltage fast charging, the charging module is a key factor. Shenzhen Kehua has developed a 40kW silicon carbide (SiC) charging module with an output voltage range of 150-1000V, suitable for 400V and 800V models. The module uses silicon carbide components, which as third-generation semiconductor materials, have higher dielectric breakdown strength, faster saturated electron drift velocity, and higher thermal conductivity compared to silicon (Si).

Silicon carbide devices exhibit excellent voltage resistance and high-voltage performance in high-voltage environments. They have high breakdown field strength and low conduction loss, which allows them to maintain high efficiency and low current loss in high-voltage environments, thereby improving device reliability and lifespan.

In terms of safety, silicon carbide devices have high voltage and high temperature tolerance, enabling them to maintain high efficiency and low thermal loss in high-voltage environments, thus ensuring vehicle safety.

Kehua’s charging module has an ultra-low output current ripple, making the charging current more stable and better suited to various models, thus protecting the battery and extending battery life.

Conclusion

The expected growth of the 800V electric vehicle market highlights the importance of addressing high-voltage fast charging challenges. By advancing charging module technology, particularly using silicon carbide components, faster, safer, and more reliable charging needs can be met. As the market continues to expand, the deployment of high-power fast charging stations will be key to supporting the widespread adoption of high-voltage electric vehicles.